MIT and Duke Researchers Use AI to Create Tougher, Eco-Friendly Plastics

Chemists from MIT and Duke created polymers that are more resistant to tearing by incorporating stress-responsive molecules identified by a machine-learning model.

Scientists from MIT and Duke University have made a significant breakthrough in the quest for more durable plastics. Using artificial intelligence, they've discovered a way to create polymer materials that are more resistant to tearing, potentially leading to a reduction in plastic waste.

The research team, led by MIT's Professor Heather Kulik, employed machine learning to identify special molecules called mechanophores. When incorporated into polymers, these molecules allow the material to withstand greater force before breaking.

"These molecules can be useful for making polymers that would be stronger in response to force. You apply some stress to them, and rather than cracking or breaking, you instead see something that has higher resilience," explained Kulik, who holds positions in both chemical engineering and chemistry departments at MIT.

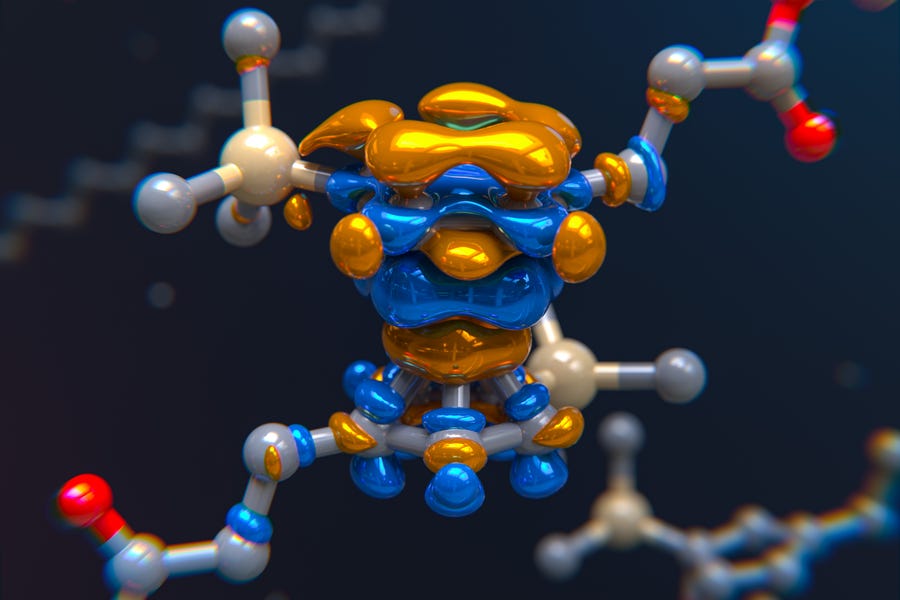

The scientists focused their efforts on a class of compounds known as ferrocenes. These organometallic molecules contain an iron atom sandwiched between two carbon-containing rings. While some ferrocenes were already known to possess mechanophore properties, the vast majority remained unexplored for this purpose.

To accelerate the discovery process, the researchers developed a neural network model. This AI system was trained on data from about 400 ferrocene compounds, including information on their structures and the force required to break them apart. The model then predicted the behavior of over 11,000 additional compounds, dramatically speeding up the search for potential mechanophores.

The AI analysis revealed two key features that likely increase tear resistance in polymers:

Interactions between chemical groups attached to the ferrocene rings

The presence of large, bulky molecules attached to both rings

Interestingly, the second trait was an unexpected finding that human chemists might not have predicted without the aid of AI.

To validate their computational results, the team synthesized a polymer material incorporating one of the AI-identified compounds, called m-TMS-Fc. This new polymer proved to be four times tougher than those made with standard ferrocene crosslinkers.

"If we think of all the plastics that we use and all the plastic waste accumulation, if you make materials tougher, that means their lifetime will be longer. They will be usable for a longer period of time, which could reduce plastic production in the long term," said Ilia Kevlishvili, the lead author of the study.

The researchers are now exploring the potential of their machine-learning approach to identify mechanophores with other desirable properties. These could include the ability to change color or become catalytically active in response to force, opening up possibilities for stress sensors, switchable catalysts, and biomedical applications like drug delivery.

This research, funded by the National Science Foundation, demonstrates the power of combining artificial intelligence with materials science to tackle pressing environmental challenges. By creating stronger, longer-lasting plastics, MIT and Duke researchers may be one step closer to a more sustainable future.